Describe the Operation of a Diaphragm Gas Valve

Working Principle of Pneumatic Actuators. The air valve uses to force compressed air behind the first diaphragm and moves it away from the middle section.

How Does A Gas Regulator Work Wonkee Donkee Tools

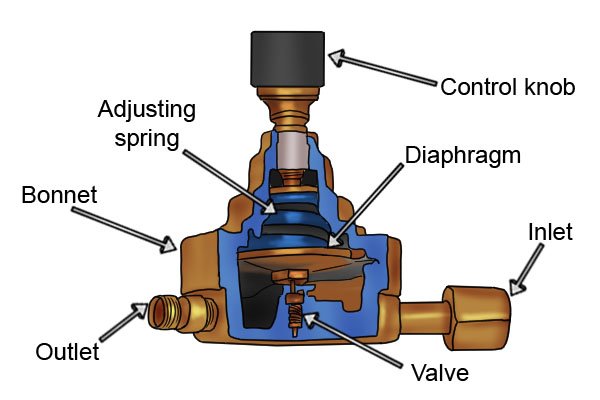

Diaphragm valves or membrane valves consists of a valve body with two or more ports an elastomeric diaphragm and a weir or saddle or seat upon which the diaphragm closes the valve.

. Pre-tensioning the spring determines the force opening the valve and when the downstream press exerts equal force on the spring the valve is in equilibrium balanced. In order to close the valve the actuator must be pressed or turned and the membrane must be pushed into the solid dam edge thus closing the valve. Pneumatic actuators use instrument air pressure to apply force on the diaphragm to move the valve actuator and then to position valve stem.

Ported vacuum from a calibrated signal port located above the throttle valve connects to the EGR vacuum chamber. The operation and construction of diaphragm valves are simple. When internal plumbing pressures reach these valves set level it triggers valve operation and effectively relieves excess pressure within the system.

At idling the EGR valve is in the closed position because of the spring pressure and lower ported vacuum. The two diaphragms are linked via a shaft through the central part in which the air valve is placed. Material can now be conveyed via the vacuum line.

The most popular type of diaphragm pump is the Air-Operated Diaphragm Pump. The Diaphragm Pump Working Principle is as simple as two valves opening and closing using air pressure to force a piston back and forth or as complicated as delicately balanced vanes that are revolved by the air. The air supply is shifted from one chamber to another with an air spool valve that is built into the pump.

This valve is a linear motion valve and it can be used to start to regulate and stop the fluid flow. This valve uses a diaphragm for its opening and closing purpose. 15Describe the operation of a diaphragm gas valve.

A diaphragm valve is different from other valves diaphragm valve doesnt have a valve disc. The use of an air motor on this type of pump allows it to be used in more than one application. Rising downstream pressure exerts force on the diaphragm Force press X area which overcomes the spring force and closes the valve.

The diaphragm pump definition comes under the classification of positive displacement pumps that utilize the grouping of the reciprocating operation of thermoplastic rubber and Teflon diaphragm. Process Systems and Operations. Describe the operation and design of a diaphragm valve variety of slurries corrosive or sticky substances are transfered from place to place Compare a relief valve to a safety valve.

Industrial Machining and Welding. They also include two chambers with a diaphragm inlet check valve and outlet check valve in each chamber. The valve body may be constructed from plastic metal wood.

Diaphragm valves are simple in construction and operation. The control valve manipulates a flowing fluid such as gas steam water or chemical compounds to compensate for the load disturbance and keep the regulated process variable as close as possible to the desired set point. The 1st diaphragm creates a pressure stroke that removes fluid from the pump.

Any gas outlet pressure change is instantly sensed and reflected back to the diaphragm. GAS analysers use diaphragm valves with internal purge option. Diaphragm valves operate as a quasi-closed system.

Diaphragm valves are well suited for process systems that need precise flow control and ones that develop operation pressure or back pressure due to system fluctuations. With this feature a continuous inert atmosphere is created around the flowpath which eliminates permeation diffusion and inboardoutboard contamination. The flowrates of these devices will not fluctuate much with that of discharge pressure which means the pump functions against the specified pump speed.

It links to a metered valve which controls the passage of the exhaust gases. The following photograph shows a cut-away control valve with a pneumatic diaphragm actuator mounted above the valve body. Like pinch valves the diaphragm completely seals off the actuating means from the process fluid a benefit for valves in sanitary service.

The regulator then repositions the diaphragm and disc to change the flow rate through the servo pressure regulator valve. When the user desires the valve to be shut the actuator is pressed andor turned and the membrane is pushed into the edge of the solid damn closing the valve. Safety Health and Plant Science.

The diaphragm is connected to the compressor with the help of stud which is molded into the diaphragm. Control valves may be the most important but sometimes the most neglected part of a control loop. It consists of a spring-loaded vacuum diaphragm.

During an open valve position the actuator is in contact with the diaphragm or inner membrane of the valve. When you complete this lesson you will be able to describe the use selection and design of the two basic types of diaphragm valves. By using gas pressure on one side of the diaphragm it keeps the diaphragm pushed down and keeps the main valve closed.

The reason why a pneumatic control valves stem position corresponds linearly to the amount of air pressure applied to the actuator is because mechanical springs tend to follow Hookes Law where the amount of spring motion x is directly proportional to applied force F kxA pneumatic actuator applies force as a function of air pressure and pistondiaphragm area F. Then the controls send an impulse to a small electric solenoid valves which in turn opens the closure. These pumps use compressed air as their power supply.

As shown in Figure 2 a valve actuator is in contact with the inner membrane or diaphragm of the valve in its open position. Diaphragm valves are also useful when pressurised air supply is not available. If material is required the vacuum starts.

Key specifications include port configuration port connections valve size media and seal material. It is a self-balancing system that works off gas valve outlet or working pressure and is independent of flow rate. It monitors the outlet pressure of the gas valve.

Diaphragm Valves employ flexible membranes to close off flow in pipes. When the gas pressure is removed the pressure from the below the diaphragm pushes it up and opens the main valve port.

What Is A Diaphragm Compressor How Does A Diaphragm Compressor Work

Comments

Post a Comment